- Howie Fenton

- |

- March 27, 2017

This in-plant primer article is the third article in a series of 12 articles designed to help dealers and print vendors understand in-plants called "In-Plant Primer: From Operations Basics to Advanced Sales Concepts." Divided into two primers of basic (101) and advanced (201) topics, this article is the third of the first six articles in the basic primer, "In-Plant Primer 101: Trends and Challenges."

In our first article we defined what an in-plant is. The second article covered the top challenges and issues. In this article, I'll share with you the typical contacts to engage in workflow conversations and how staffing levels impact the number and severity of bottlenecks.

Key Take Aways

- The size of the in-plant determines who to talk with. In smaller in-plants, you may be able to talk to anyone. In larger in-plants, customer service reps (CSRs) are good resources. They can help you understand the workflow, issues and introduce the subject matter experts in production.

- With more in depth questions, the CSRs in larger in-plants may pass a phone call to the subject matter expert in design, prepress or mailing.

- In-plants are staffed differently than commercial printers; most lack sales, marketing, human resources, and accounts receivable staff.

Who are the Typical In-plant Contacts to Engage?

It doesn't matter if you're a customer or a salesperson, who you can talk with in an in-plant print center is based on the number of staff that work at the in-plant. In the very small shops with only a few staff, you can often talk to anyone because everyone has to know everything. However, as the in-plant staff increases, the responsibilities are often more focused and there may be fewer people that can talk with you. According to In-Plant Graphics Magazine (December 2016), the top ten in-plants have staff ranging from 100-554 but these are the exceptions, not the rule. In the recent PRIMIR study Digital Printing Technology's Influence on the U.S. In-Plant Printing Market that IMG worked on with IDC, we found 88% of in-plants had less than 20 staff and 55% had less than 5 staff. In very small in-plants with only a few staff, you may talk to everyone or whoever answers the phone. In larger in-plants, there are generally managers, CSRs staff, graphic designers, prepress, printing, finishing, and mailing staff. In the larger shops, you often have a CSR that acts as a liaison between customers and production staff. The CSR can be a valuable asset to better understand the workflow and possible issues such as bottlenecks, brand control (using different logos) and mistake-prone procedures. These issues are all candidates for software automation. With a basic understanding of the workflow and potential issues you can talk directly to the subject matter experts, such as the graphic designer for design issues, the prepress person for file concerns, and the press and finishing staff for quality issues.

Sales and Marketing Conversations are Frowned On by Parent Organizations

Staff positions are almost identical to those found in commercial printing with a few exceptions, such as those associated with sales and marketing. As we will discuss throughout this series, sales and marketing is often frowned on by the administration of corporate and in-house print centers. Typically, the mission of the in-plant is to provide service to internal customers – not to sell or market to them. Unfortunately, that places in-plants at a significant disadvantage because sales people from the local commercial printers are knocking on the door of the in-plant's customers. In addition, without a marketing person, it becomes more difficult to understand how the in-plant's customers' needs are changing. There are some in-plants that have fought the battle and are allowed to either staff or assign sales and marketing responsibilities to other staff members. For example, some in-plant managers dedicate half their time for sales and marketing and some in-plants assign sales and marketing responsibilities to the customer service staff. Those are often larger in-plants with well-established needs including many that are government in-plants and transactional in-plants with a high volume of bills and statements. For most, especially the graphic arts in-plants, they often struggle as declines in volume occur. They would benefit from both sales and marketing efforts. These efforts can help quantify the need to diversify the product mix to include more value-added services like wide format printing and variable data printing. More experienced in-plant managers and administrators can make the case for sales and marketing.

Small and Large Shop Staffing, Contact Point and Bottlenecks

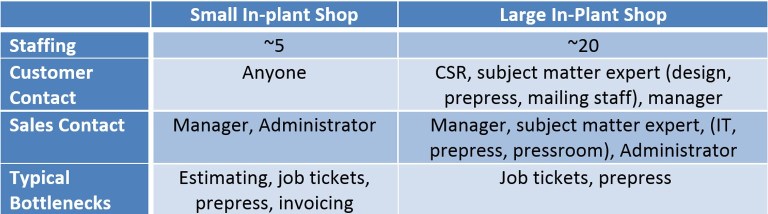

The table above shows the difference in staffing, specialization and likely bottlenecks in small and large in-plants. In the smaller in-plants customer information about daily work is shared with everyone, while in larger in-plants the information may be known only by staff working on specific jobs (i.e. CSR). Who should you to talk to about investments such as software automation? In smaller shops it may only be the manager and the administrator. In larger facilities it may require conversations with other subject matter experts such as IT staff (interfacing with existing systems), estimators (to help develop online pricing), CSR's (creating a shopping cart) and prepress staff (often considered subject matter experts on software). Smaller in-plants often have multiple bottlenecks due to the lack of specialized staff, but each of those bottlenecks are less of an impact. In contrast, larger facilities typically have fewer, but more serious bottlenecks.

Summary

- Do some homework before you approach an in-plant to understand the size of the operation and the type of work produced. For example, in our first article we mentioned that transactional in-plants primarily print bills and statements.

- Know the size and type of in-plant to understand the likely print applications and volumes. Knowing what they do and how much they produce (based on size) can help drive more detailed conversations and better probing questions.

- Consider using the questions to ask list that RSA has posted in our Partner Resource portals or request a copy of "What to Listen for and What to Ask" from an in-plant expert at Rochester Software Associates (RSA).

In our next article, I'll talk about what significant changes in technology have happened in the last five years and how they impact and improve in-plants.

Don't miss any articles like these ever again; subscribe to RSA's email updates and we'll automatically alert you when articles like these are published.