- Howie Fenton

- |

- January 30, 2017

This is the first of a series of articles designed to introduce internal print production, corporate, in-house or in-plant production centers, as they are often called. Comprised of a 12-article series, two eBooks and a webinar, the initiative is called "In-Plant Primer: From Operations Basics to Advanced Sales Concepts." The goal is to provide important background information as well as detailed information to help dealers and print vendors understand in-plants. This is the first article of the first six-article series and will soon be compiled into a convenient eBook titled: "In-Plant Primer 101: Trends and Challenges." In this series, I'll cover the basics of the in-plant market. The second primer and eBook will be called: "In-Plant Primer 201: Operational and Financial Concerns."

Key Take Aways

- In-plants are found in a wide variety of companies and organizations and offer a wide range of services such as design, copy, printing and other services.

- In-plants are often divided into two categories: one that prints primarily bills and statements for their parent company (transactional printers), and others, called graphic arts in-plants, that don’t specialize in specific documents.

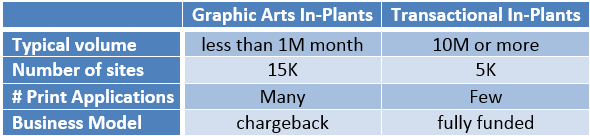

- Transactional in-plants print much higher volumes than graphic arts in-plants (10M/month vs 1M month), but there are significantly fewer transactional in-plants than graphic arts in-plants (1:4 ratio).

What is an in-plant? What do they do? How do they fit in the customer environment?

An in-plant service provider is typically a small printing department within a larger organization. They may offer design, copy, printing and mailing services. In the past, they have also have been called print rooms and CRDs (central reprographics department). In-plants may offer digital printing, offset printing, or both. In-plants are common in large companies and organizations that have: high volume demands for printing and/or mailing needs, security concerns, or require fast turnaround. For example: insurance, financial, healthcare, and government agencies often have in-plants that offer printing and mailing of transactional documents (bills, statements, explanation of benefits, etc). Universities often print stationery products such as business cards, course packs, letterhead, and stationery. School districts use in-plant printers for course materials and lessons plans.

Types of in-plants

Throughout this series we will discuss in-plants into two categories: transactional and graphic arts in-plants. The transactional in-plants print documents such as bills, statements, policies, marketing collateral, forms, and direct mail. Graphic arts print a wider variety of products including stationery products, forms, publications, educational course packs, posters and signs. The two main differences between transactional and graphic arts in-plants are volume and the number of in-plants. Transactional in-plants print much higher volumes than graphic arts in-plants. For example, a transactional in-plant may print more than 10 million pages per month compared to a graphic arts in-plant that prints less than one million pages per month.

However, there are significantly fewer transactional printers. In the recently published NPES/PRIMIR study called, "Digital Printing Technology’s Influence on the U.S. In-Plant Printing Market" that we (IMG) developed with IDC, we estimated that there were about 19,000 in-plants, comprised of 75% graphic arts and 25% transactional in-plants.

In an article later in the in-plant primer 101 series we will talk more about different business models, why this is important to you and how it impacts decision-making. For example, does the in-plant charge back their customers with the goal of breaking even financially at the end of the year or is it fully funded by the parent organization? Typically graphic arts in-plants charge back while transactional in-plants are fully funded.

Don't Miss Articles Like This

Subscribe to RSA's email updates and we'll automatically alert you as each article is published.

Learn more about in-plant print centers. Visit RSA's resources, packed with in-plant information or contact an RSA Business Development Manager.