- Howie Fenton

- |

- November 19, 2025

As we approach the end of the year, the print industry stands at a pivotal turning point. Technology continues to accelerate—driven by automation, AI, and production inkjet—while economic, supply-chain, and labor challenges pressure every business model. Rather than viewing these forces as disruptions, leading printers are using them as catalysts for modernization, diversification, and sustainable growth.

Insights drawn from PwC’s 2025 Digital Trends in Operations Survey, and observations from PRINTING United Expo Orlando 2025, highlight the key forces reshaping print production and outline strategies to increase productivity, remain competitive, and achieve long-term resilience.

Generative AI and Personalization

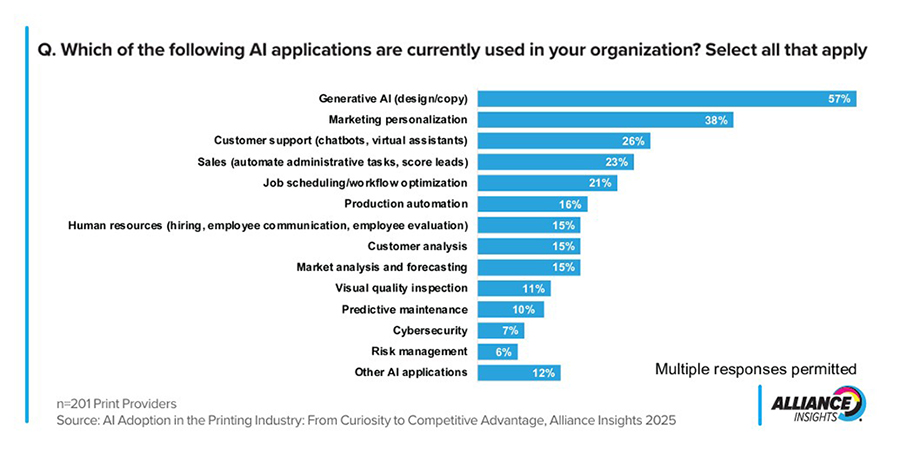

AI continues to dominate industry discussion—but the conversation has matured from curiosity to implementation. According to Printing United Alliance’s AI Adoption in the Printing Industry (2025), 85% of PSPs believe AI is now critical to competitiveness, with most already piloting AI in estimating, prepress, and workflow automation. Generative AI tools such as ChatGPT, Adobe Firefly, and Jasper are transforming marketing and creative operations. They allow printers to deliver personalized copy, dynamic imagery, and campaign analytics that bridge print and digital media. Nearly 60% of printers plan to use AI for marketing design and segmentation, and over 60% already leverage it for campaign analytics.

In the recent publication Turning Curiosity Into Competitiveness, case studies from firms such as Olympus Group and Image Options illustrate how AI is being applied in real time—from estimating and proposal writing to creative development and campaign analytics. The takeaway: printers aren’t waiting for perfect AI tools—they’re testing, iterating, and using early wins to guide broader automation strategies.

What This Means for Printers:

AI isn’t replacing creativity—it’s accelerating it. Printers that integrate AI into campaign workflows will shorten turnaround times, increase personalization, and transition from print vendors to marketing solution providers.

Digital Transformation Moves Beyond Print

More than 70% of PSPs have diversified into creative, mailing, and analytics services (PRINTING United 2025). Customers now expect omnichannel integration—print synchronized with digital advertising, email, and social media. For in-plants, that means evolving into communication hubs with self-service portals, automated approvals, and data-connected workflows.

What This Means for Printers:

Digital transformation is less about adopting software and more about aligning data and workflows across platforms. Printers that integrate print MIS, CRM, and marketing automation systems gain visibility, improve customer experience, and position themselves as strategic partners in content delivery.

Inkjet Ascends While Toner and Offset Rebalance

Production inkjet continues to outperform both toner and offset for short-run, on-demand, and variable applications. Over half of PSPs now operate inkjet systems, and another 20% plan adoption by 2026 (PRINTING United, Production Digital Printing 2025). Inkjet’s appeal lies in its lower cost per page, faster throughput, reduced waste, and offset-quality output. Printers report an average 9% reduction in paper waste and 8% increase in profit margins after migrating from toner.

What This Means for Printers:

Inkjet is no longer just an upgrade—it’s a strategic pivot. It improves utilization rates, shortens setup times, and reduces energy costs. The shift is from press capacity to data capacity, where smarter workflows and variable applications drive new profitability.

Automation and AI Redefine Workflow Efficiency

Automation is now the industry’s most reliable lever for margin protection. Nearly 80% of PSPs have automated at least part of their workflows, while in-plants rank automation as their top reason for equipment investment (PRINTING United, Production Digital Printing 2025). AI-enabled systems from leading vendors are reducing downtime by over 20% through predictive maintenance, self-calibrating diagnostics, and smart print routing. Automation of preflight, imposition, and production scheduling allows facilities to process thousands of jobs per day with fewer touchpoints and higher consistency.

These findings align with a broader industry pivot toward predictive, data-driven operations. PRINTING United’s 2025 Commercial Printing Report reinforces this momentum: over 70% of printers list productivity as their top business priority, and more than half plan to invest in bindery and finishing automation. Inkjet and AI adoption follow closely, signaling that efficiency, not expansion, now defines competitiveness.

What This Means for Printers:

Automation is the baseline for competitiveness. If you’re not automating, you’re falling behind. The next step is predictive operations—where connected systems not only automate but anticipate. Printers that combine AI-driven monitoring with real-time dashboards will achieve lights-out efficiency and measurable ROI. These efficiency gains, which will be discussed in the next blog post, are vital as tariffs and supply costs rise, reinforcing why workflow automation is now both a technical and financial imperative.

Diversification Through Packaging, Wide-Format, and Embellishment

With commercial print volumes declining, diversification is now the strongest path to growth. PRINTING United’s In-Plant Equipment Investment Trends (2025) found that 86% of in-plants now operate wide-format systems, and 10% are adding embellishment or packaging capabilities. These expansions open new markets in retail, décor, and prototype packaging while stabilizing revenue.

Case studies presented at the PRINTING United Expo 2025 highlight how printers such as Color Ink, Premier Press, and Quad diversified successfully into packaging, promotional, and branded products. Each printer leveraged existing expertise and vendor relationships to expand into adjacent markets with higher margins and stronger client retention. These examples demonstrate that diversification isn’t about adding services—it’s about expanding the customer value chain.

What This Means for Printers:

Diversification builds resilience. Wide-format, embellishment, and packaging offer higher margins and stronger client relationships. The key is modular workflows, cross-trained teams, and adaptable finishing systems.

RSA’s Role in Connected Automation

As automation becomes the foundation of modern print operations, Rochester Software Associates (RSA) stands out as a proven enabler of workflow transformation. Its integrated suite—WebCRD, ReadyPrint, QDirect, and ImpactVDP—connects every production stage from job submission to delivery. WebCRD automates print ordering, approvals, and fulfillment. ReadyPrint streamlines prepress setup and imposition. QDirect optimizes load balancing and intelligent print routing. ImpactVDP enables scalable, data-driven personalization.

What This Means for Printers:

RSA’s ecosystem transforms automation from a series of tools into a connected business strategy—linking data, people, and systems for measurable efficiency, profitability, and resilience.

3 Take Home Points

- Technology is redefining competitiveness. Automation, AI, and production inkjet have moved from “future initiatives” to essential profit drivers. Printers adopting these tools are reporting double-digit gains in throughput, waste reduction, and utilization.

- Diversification is the new growth engine. As traditional commercial volumes decline, providers are expanding into packaging, wide-format, and data-driven personalization. The shift from commodity printing to value-added communication services is separating market leaders from laggards.

- Integration builds long-term resilience. The most successful printers connect their workflows end-to-end—linking web-to-print, MIS, analytics, and prepress automation into unified digital ecosystems. This alignment improves efficiency, enhances customer visibility, and positions print operations as indispensable partners in multichannel marketing.

7 Recommendations

- Automate the essentials: Evaluate every workflow stage—intake, scheduling, prepress, and finishing—for automation opportunities.

- Invest in inkjet strategically: Conduct cost/benefit and ROI modeling to determine when it makes sense to invest.

- Integrate your data systems: Connect web-to-print, MIS, and job floor tracking tools to a streamlined approach to orders and production costs.

- Diversify revenue streams: Add high-margin services such as embellishment, wide-format, merchandise, or personalization.

- Upskill the workforce: Launch consultant or vendor-based training in automation, AI, and sustainability to attract and retain Gen Z talent.

- Measure sustainability as performance: Track waste, bottleneck rates alongside productivity metrics.

- Benchmark continuously: Compare operational KPIs quarterly against leaders to benchmark and maintain competitive positioning.

2026 Print Production Trends: Technology and Market Shifts

As we approach the end of the year, the print industry stands at a pivotal turning point. Technology continues to accelerate—driven by automation, AI, and production inkjet—while economic, supply-chain, and labor challenges pressure every business model. Rather than viewing these forces as disruptions, leading printers are using them as catalysts for modernization, diversification, and sustainable growth. As automation becomes the foundation of modern print operations, Rochester Software Associates (RSA) stands out as a proven enabler of workflow transformation. Its integrated suite—WebCRD, ReadyPrint, QDirect, and ImpactVDP—connects every production stage from job submission to delivery.