- Howie Fenton

- |

- May 09, 2023

For in-plants, investing in new software or hardware offers numerous benefits, such as increased efficiency, reduced turnaround time, improved customer satisfaction, and lowered costs. The problem, however, is that management is often hesitant to invest in increasing productivity. This is the second blog in a series about preparing to overcome management investment objections. The first blog discussed nine steps to help prepare you to increase trust and enhance collaboration. In this installment, we discuss the ten steps in your due diligence process.

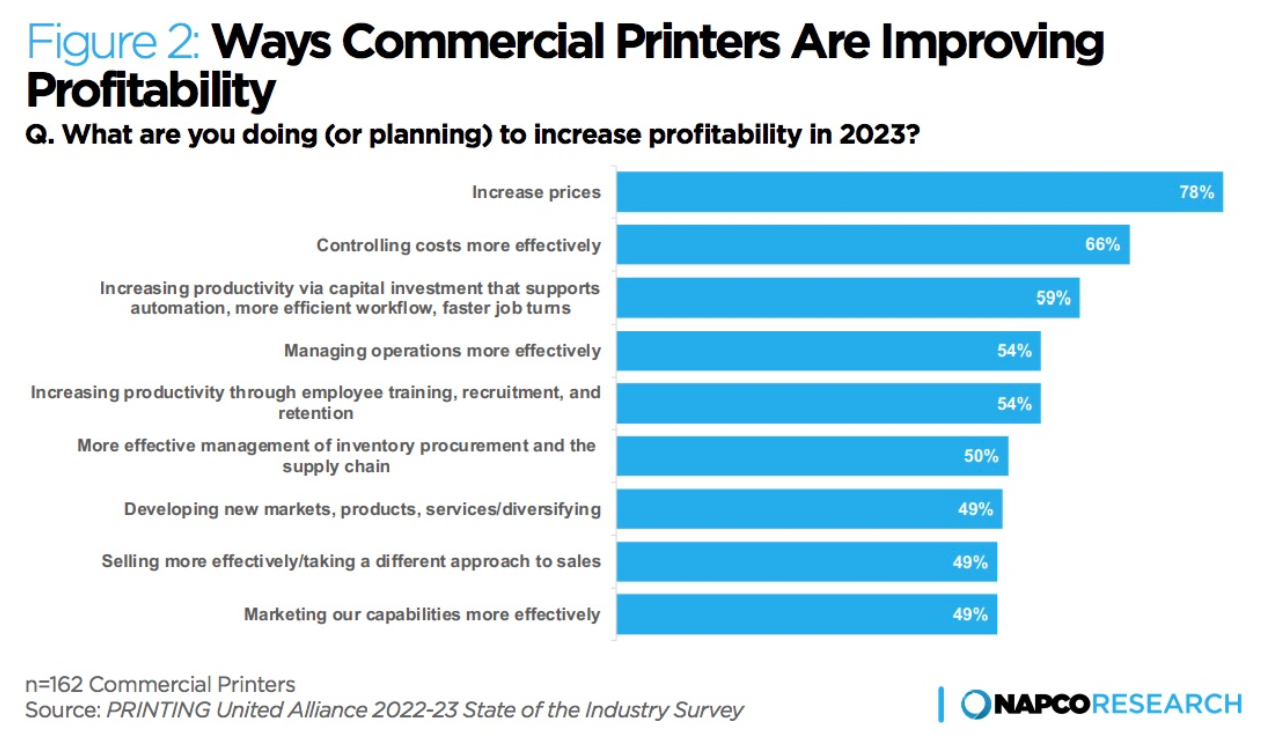

In the previous blog, we shared a figure from a NAPCO study showing that price was one of the top challenges for printers. This blog includes a figure from the Printing United Alliance study, "Printing United Alliance 2022-23 State of the Industry Survey", describing how printers plan to increase profitability in 2023. For in-plants, that may be more accurately called meeting your financial objectives. As shown in the figure below, four of the top five answers focused on increasing productivity.

As you can see in this figure, three out of four of the top responses include: controlling costs, increasing productivity via capital investment, and managing operations more efficiently. While training and procedural improvements will get you part of the way, the only way to make a significant breakthrough in performance requires investments in hardware and/or software. In addition to building trust and collaboration, you have to go through a detailed due diligence process. Here are ten steps to consider in your due diligence process.

- Unexpected objections. Objections can appear from unexpected places (IT, CFO, facilities, etc.). It’s important to understand the challenges. Gather feedback from management and stakeholders to understand their concerns and reservations about the investment.

- Address concerns. Be prepared to address specific objections, such as initial costs, implementation challenges, or training requirements. Offer well-researched solutions to mitigate these concerns and demonstrate your commitment to a smooth transition.

- ROI. You should calculate the return on investment (ROI). Provide a detailed cost-benefit analysis illustrating the potential return on investment (ROI) and payback period. Highlight anticipated cost savings from increased efficiency, higher productivity, and reduced waste. Feel free to ask RSA about their ROI calculator.

- Cost-Benefit Analysis (CBA). Conduct a CBA evaluating the costs of acquiring, implementing, and maintaining the new equipment against the expected benefits, such as increased productivity or reduced costs. Productivity and reduced costs can be quantified using hours saved multiplied by cost per hour. Reduced costs can also result from less rework, also calculated using hours saved multiplied by cost per hour and cost of materials (paper, plates, etc.)

- Risk Assessment. Consider preparing a risk analyses that identifies potential risks such as compatibility issues, downtime, or maintenance concerns. Assess the likelihood and impact of each risk and develop mitigation strategies. For example, downtime is always an important risk factor when moving to a new printing technology such as inkjet printing. But, before requesting the most expensive maintenance contract from an inkjet press vendor, talk to other in-plants about their need for inkjet maintenance.

- When introducing new products, emphasize the potential new revenue streams. To accomplish this requires market research to understand the demand for the new product. This can be done through surveys, focus groups, interviews, and analyzing existing data or reports from NAPCO or Keypoint Intelligence. To remain consistent, you should use the same data in the ROI for a sales forecast for your new product. Include sales projections each year of three years, as well as cost and price per product and year-end revenue.

- Training and support. Emphasize the availability of training and support for employees during the implementation process. This can alleviate concerns about the learning curve and demonstrate that the company is investing in both technology and its workforce.

- Proof of concept, a pilot project, or a phased approach. Propose a proof of concept, pilot project or phased implementation plan to minimize risk and allow management to see the benefits firsthand before committing to a full-scale rollout. Years ago, when Web to Print was first introduced we used to implement Web to Print with a subset or small group of customers, to prove that it worked and that they would use it. This approach can also help identify any issues and refine the implementation strategy.

- Detailed implementation plan. Present a clear implementation plan, including timelines, resource allocation, and responsibilities. This demonstrates that you have considered the practicalities of the implementation and can help alleviate concerns about potential disruption.

- Monitor and report progress. If your proposal is approved, keep management informed of the progress throughout the implementation process. Share successes, challenges, and learnings to demonstrate the value of the investment and build confidence in your ability to manage the project.

The importance of investing in new technology to enhance productivity to reduce time, cost, and pricing will never go away. As an in-plant, your customers will compare your turnaround time and cost to outside providers. Therefore, it is crucial for in-plant managers to prepare to overcome management objections by working through a due diligence exercise like the one I've outlined here.

Get Expert Advice to Create a Due Diligence Plan to Overcome Investment Objections

Get expert insights, advice, and examples like those in the blog to enable you to create a due diligence plan so your technology investment plan is approved.