There is no way we could have survived the increase in volume that we have, with the same staff, without this software.

Farmington Public Schools had a problem. The school district, in Farmington, Minnesota, needed to eliminate wasted time and money in their printing operations. Teachers were spending too much time standing in line, making their own copies instead of working one-on-one with students or developing lesson plans.

Peggy Johnson, Print Center Manager, knew the district needed to drive volume to a centralized print center, where print jobs could be produced on more efficient production equipment. In addition, with the anticipated increase in centralized volume, Johnson knew she would need software that could automate production by eliminating steps at each stage of a document’s workflow.

Enter RSA

Rochester Software Associates, Inc. had seen it all before. RSA demonstrated to Ms. Johnson how numerous school districts have achieved increases in centralized volume by adopting RSA solutions. Consistently, these schools are able to handle the increased volume without increasing staff.

Farmington embraced the RSA solution, including WebCRD, the award-winning Web-to-Print offering. Teachers and staff submit electronic jobs to be printed at the centralized print shop, 24x7. Users also have access to job status by web or email, so they don’t need to interrupt the print operators.

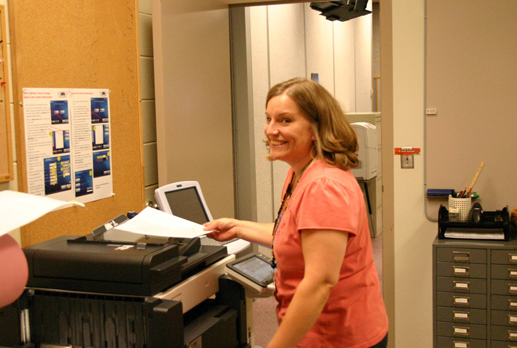

Farmington also adopted QDirect.SCAN, RSA’s Scan to Print Center offering. If teachers have a hard- copy document to duplicate, they can walk up to a Multi-Function Printer (MFP) and scan the original document. Users enter job ticketing information using a friendly touchscreen interface.

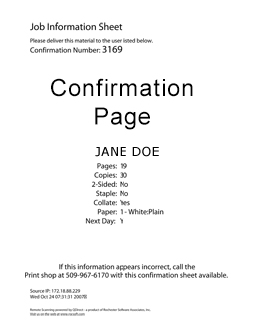

The job is transmitted to the print center electroni- cally and the user receives a confirmation sheet, printed directly at the MFP. Users spend less time at the copier and receive a higher quality result, using more finishing options and paper stock than they might have available locally.

In either case, the jobs arrive at the print center in electronic form. There is no need for an operator to rekey any ticketing information, saving steps and eliminating mistakes.

Business rules dictate if a job should be printed automatically or be held for an operator. Jobs can be batch printed based on characteristics such as job size or destination. This helps with courier delivery and is one of the ways schools are able to promise that jobs submitted by 12:30pm will be on a teacher’s desk before class the next morning.

Teachers like the reliability of the print center, and having a choice of job submission methods, web-based or hardcopy. If they are more comfort- able with a copier than a computer, they can use Scan to Print Center.

Making a Difference

The most noticeable difference for us is that we have been able to keep up with the increasing demand without having to hire another person in our already quite cramped space.

Farmington’s print volume has increased from 8 million impressions per year in 2006 to nearly double, with 15 million impressions per year expected in 2009.

Ms. Johnson acknowledges that Farmington never could have achieved this volume with their old system. Indeed, within three years of the initial implementation, the school’s centralized volume increased to the point that Farmington needed to install new production printers!

The good news is that WebCRD and QDirect can accommodate a broad range of production equipment. Farmington was able to choose the right printers for their needs, without being locked in to one vendor.

"There is no way we could have survived the increase in volume that we have, with the same staff, without this software,“ Johnson recalls.

The increased demand actually outpaced the equipment, leading to acquisition of faster printers.

“The printers can no longer keep up with the WebCRD and QDirect Software," continues Johnson. "The efficiencies gained by RSA have been invaluable".

While WebCRD and QDirect.SCAN are available separately, they go together like peanut butter and jelly. Each is great on its own, but combined, they are even better. For example, a user can scan, ticket, and submit a hardcopy job using QDirect.SCAN from an MFP. That scanned job can automatically be placed in the user’s WebCRD archive. Then, next semester or next year, when a teacher needs copies of

that same document, she will be able to order reprints from her desktop using WebCRD. There is no need to scan the job again!

"The teachers have also commented about the added benefit of having a 'job history' and being able to view their proof and knowing what their copies will look like when they receive them," observes Johnson.

Then and Now

"Our former system didn't allow us to just release jobs; we had to set the jobs up ourselves. We have now been able to release hundreds of jobs before leaving the print center alleviating many hours of overtime,” reports Johnson.

“In past years we have spent over 200 hours in overtime for the hourly workers, not including manager time. I have to say that customer service has always been a priority at this print shop, however, it was always at the print shop employees’ expense."

"The most noticeable difference for us is that we have been able to keep up with the increasing demand without having to hire another person in our already quite cramped space,” Johnson recalls. "We are mov- ing to a new facility where we will be able to add more equipment and possibly another employee, but this system bought us much needed time!!"

What does Ms. Johnson like best about the solution? “The fact that the end user sets up their job and jobs can be released and printed without having to have someone always on the premises when its hap- pening. It streamlined everything for us! If a mistake is made, it is because the customer entered wrong information, and they can see that on the confirmation sheet.”

Before adopting the RSA solution, Farmington was processing about 5,000 jobs/month and upwards of 1 million impressions/month. Now, the print center produces twice as many jobs (10,000 jobs/month) and 50% more impressions (1.5 million impressions/month).

There are economies of scale, as those jobs migrate to centralized printers. The print shop calculated that the external cost to print a black and white impression ranges from $.0055 to as much as $.013, but centrally the cost is as low as $.0022. That’s a savings of 60% to 80%! For color, the cost drops from $.13 to $.04, or nearly 70% less!

When an organization is able to double the number of jobs processed with no increase in staff, and save money on each and every impression, there are lessons to be learned. And where better to learn than Farmington Public Schools?